-

Call

-

Whatsapp

9825014048

-

Location

Blog

BLOG

The Advantages of Heatless Air Dryers

In the realm of industrial processes, maintaining high-quality compressed air is critical for ensuring operational efficiency and protecting equipment. One of the key components in achieving this is the air dryer. Among various types, heatless air dryers stand out due to their efficiency and reliability. This comprehensive guide explores the advantages of heatless air dryers and their benefits for industrial processes.

Understanding Heatless Air Dryers:

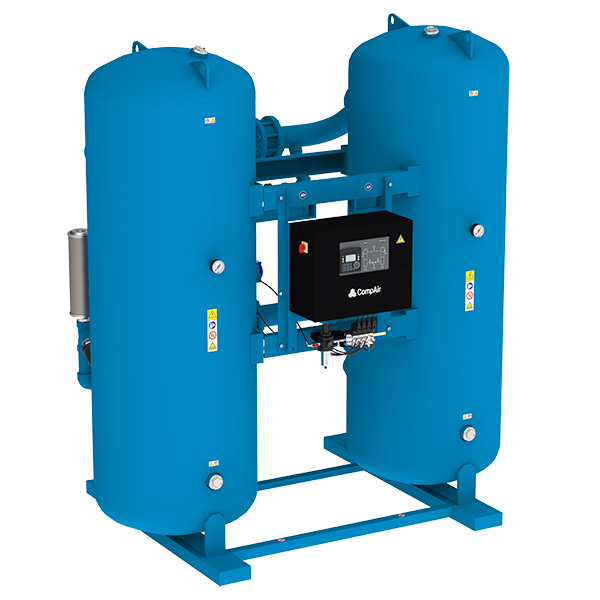

Heatless air dryers, also known as pressure swing adsorption (PSA) dryers, operate without the need for external heat. They use a process of adsorption to remove moisture from compressed air. The system consists of two towers filled with a desiccant material, such as activated alumina or molecular sieves. While one tower dries the compressed air, the other regenerates the desiccant by purging a small portion of the dry air through it. This cycle alternates between the towers, ensuring a continuous supply of dry air.

Advantages of Heatless Air Dryers:

1. High Efficiency in Moisture Removal:

Heatless air dryers are highly efficient in removing moisture from compressed air. They can achieve extremely low dew points, often as low as -40°F to -100°F, ensuring that the air is free from moisture and suitable for sensitive industrial applications.

2. Energy Savings:

One of the significant advantages of heatless air dryers is their energy efficiency. Since they do not require external heat for the regeneration process, they consume less energy compared to heated dryers. This can lead to substantial energy savings, especially in large-scale industrial operations.

3. Lower Maintenance Requirements:

Heatless air dryers have fewer moving parts and simpler designs, which result in lower maintenance requirements. The absence of heaters or blowers reduces the risk of mechanical failures and the need for regular maintenance, making them a cost-effective option for many industries.

4. Consistent Performance:

Heatless air dryers provide consistent performance regardless of environmental conditions. Unlike heated dryers that may be affected by ambient temperature fluctuations, heatless dryers operate effectively in a wide range of temperatures, ensuring reliable moisture removal.

5. Space Efficiency:

Heatless air dryers are typically more compact than their heated counterparts. Their smaller footprint makes them ideal for installations where space is limited, allowing for more flexible placement in industrial settings.

6. Environmental Benefits:

Heatless air dryers offer environmental benefits by reducing energy consumption and minimizing heat generation. This can contribute to a lower carbon footprint for industrial operations, aligning with sustainability goals and regulatory requirements.

7. Cost-Effective Operation:

The overall operational costs of heatless air dryers are often lower than other types of dryers. Their energy efficiency, combined with reduced maintenance needs and longer lifespan, results in significant cost savings over time.

8. Versatility in Applications:

Heatless air dryers are versatile and can be used in a variety of industrial applications. They are suitable for any process that requires dry compressed air, including pharmaceuticals, food and beverage, electronics, and manufacturing industries.

Applications of Heatless Air Dryers in Industry:

1. Pharmaceutical Industry:

In the pharmaceutical industry, maintaining the purity of compressed air is crucial. Heatless air dryers ensure that the air is free from moisture and contaminants, which is essential for the production of high-quality pharmaceutical products.

2. Food and Beverage Industry:

The food and beverage industry requires dry and clean air to prevent contamination and maintain product quality. Heatless air dryers provide the necessary air quality, ensuring compliance with stringent hygiene standards.

3. Electronics Manufacturing:

In electronics manufacturing, moisture in compressed air can cause significant damage to sensitive components. Heatless air dryers effectively remove moisture, protecting electronic parts and improving product reliability.

4. General Manufacturing:

General manufacturing processes often rely on dry compressed air for various operations. Heatless air dryers enhance the efficiency and reliability of these processes by providing consistently dry air.

Conclusion:

Heatless air dryers offer numerous advantages for industrial processes, including high efficiency in moisture removal, energy savings, lower maintenance requirements, and consistent performance. Their compact size, environmental benefits, cost-effective operation, and versatility make them an excellent choice for various industrial applications. By investing in heatless air dryers, industries can improve operational efficiency, protect equipment, and achieve significant cost savings, all while contributing to environmental sustainability. When selecting an air dryer, consider the specific needs of your application and the benefits that heatless air dryers can provide.

FAQs

Frequently Ask Questions

A heatless air dryer, also known as a pressure swing adsorption (PSA) dryer, removes moisture from compressed air without using external heat. It operates using a desiccant material that absorbs moisture from the air. The system consists of two towers, one drying the air while the other regenerates the desiccant.

Heatless air dryers use a cycle of adsorption and desorption. Compressed air passes through one tower filled with desiccant material, which absorbs the moisture. A small portion of the dry air is then used to regenerate the desiccant in the other tower. The process alternates between the two towers to ensure continuous drying.

The main advantages include: High efficiency in moisture removal: Achieves low dew points (-40°F to -100°F). Energy savings: No external heat required, reducing energy consumption. Lower maintenance requirements: Fewer moving parts and simpler design. Consistent performance: Effective in various environmental conditions. Space efficiency: Compact design suitable for limited spaces. Environmental benefits: Reduced energy consumption and heat generation. Cost-effective operation: Lower overall operational costs. Versatility in applications: Suitable for various industrial processes.

Heatless air dryers are used in a wide range of industries, including: Pharmaceutical: Ensuring air purity for high-quality product production. Food and Beverage: Preventing contamination and maintaining product quality. Electronics Manufacturing: Protecting sensitive components from moisture damage. General Manufacturing: Enhancing efficiency and reliability of operations requiring dry compressed air.

Heatless air dryers do not require external heat for the regeneration process, which significantly reduces energy consumption compared to heated dryers. This energy efficiency can lead to substantial cost savings, especially in large-scale industrial operations.

Heatless air dryers have lower maintenance requirements due to their simple design and fewer moving parts. Regular maintenance typically involves inspecting and replacing the desiccant material as needed and ensuring the system operates correctly. This reduces the risk of mechanical failures and minimizes downtime.

Yes, heatless air dryers are more environmentally friendly due to their reduced energy consumption and minimal heat generation. This contributes to a lower carbon footprint for industrial operations, aligning with sustainability goals and regulatory requirements.

Yes, heatless air dryers provide consistent performance in a wide range of environmental conditions, including extreme temperatures. Unlike heated dryers, their operation is not affected by ambient temperature fluctuations, making them reliable for various applications.

By providing dry compressed air, heatless air dryers prevent moisture-related damage to industrial equipment. This protection extends the lifespan of machinery and reduces the need for frequent repairs or replacements, resulting in cost savings.

Yes, heatless air dryers are cost-effective due to their energy efficiency, lower maintenance needs, and long-term operational reliability. These factors contribute to reduced overall operational costs and make them a wise investment for industrial processes.

When selecting a heatless air dryer, consider the following factors: Air quality requirements: Ensure the dryer meets the specific moisture removal needs of your application. Size and capacity: Choose a dryer with the appropriate capacity for your compressed air system. Operating conditions: Ensure the dryer can perform effectively under your environmental conditions. Energy efficiency: Look for models that offer energy-saving features. Maintenance needs: Consider the ease of maintenance and availability of replacement parts. Cost: Evaluate the initial investment and long-term operational costs.