-

Call

-

Whatsapp

9825014048

-

Location

Blog

BLOG

Benefits of Screw Compressor Combi Coolers

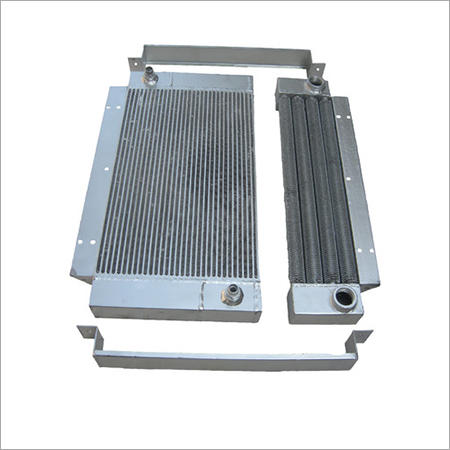

In the world of industrial applications, screw compressors are renowned for their efficiency and reliability. However, integrating combi coolers into these systems is essential to maximise their performance and lifespan. Combi coolers combine air and oil cooling functions and are crucial in maintaining optimal operating conditions.

Let's explore the various benefits of screw compressor combi coolers and how they enhance both performance and reliability.

Understanding Screw Compressor Combi Coolers:

Screw Compressor combi coolers are designed to cool both the air and the oil used in the compressor. These cooling systems ensure the compressors operate within the ideal temperature range, preventing overheating and maintaining efficiency. By managing the thermal load effectively, combi coolers help sustain the compressor's performance and extend its operational life.

Critical Benefits of Screw Compressor Combi Coolers:

1. Improved Thermal Management:

One of the primary benefits of combi coolers is their ability to manage the thermal load of screw compressors. By cooling the air and oil, these systems ensure that the compressor operates within optimal temperature ranges. This prevents overheating, which can lead to component wear and failure, thus maintaining the efficiency and reliability of the compressor.

2. Enhanced Efficiency:

Proper cooling is essential for maintaining the efficiency of screw compressors. When the air and oil are kept at optimal temperatures, the compressor can operate more efficiently, consuming less energy. This reduces operational costs and contributes to a greener, more sustainable operation by lowering the overall energy consumption.

3. Extended Equipment Lifespan:

Overheating can cause wear and tear on compressor components, leading to premature failure. Combi coolers help mitigate this risk by maintaining ideal operating temperatures, thus extending the compressor's lifespan. This translates to lower maintenance costs and a less frequent need for component replacements.

3. Improved Reliability:

By preventing overheating and ensuring stable operating conditions, combi coolers enhance the overall reliability of screw compressors. This is particularly important in industrial applications where unexpected downtime can result in substantial financial losses. Reliable cooling means fewer breakdowns and more consistent performance.

4. Compact and Integrated Design:

Combi coolers typically feature a compact and integrated design, combining air and oil cooling functions in a single unit. This space-saving design simplifies installation and maintenance, making it easier to incorporate into existing compressor setups without requiring significant modifications.

5. Reduced Maintenance Requirements:

With adequate cooling provided by combi coolers, compressors experience less thermal stress, reducing the frequency and severity of maintenance requirements. This results in less downtime and cheaper maintenance expenses, allowing for more continuous and productive operation.

6. Versatility and Adaptability:

Screw compressor combi coolers are versatile and can be adapted to various industrial applications. Whether used in manufacturing, automotive, or any other industry that relies on compressed air systems, these coolers can be tailored to meet specific cooling needs, ensuring optimal performance across different environments.

Implementing Screw Compressor Combi Coolers:

To fully leverage the benefits of combi coolers, it is crucial to ensure proper selection, installation, and maintenance. Here are some tips:

1. Select the Right Combi Cooler:

Choose a combi cooler that matches the specific requirements of your screw compressor, taking into account factors such as cooling capacity, ambient temperature conditions, and the operational demands of your application.

2. Professional Installation:

Installing the combi cooler requires expertise, so choose someone who knows their way around compressor systems. Proper installation is critical to achieving optimal cooling performance and avoiding potential issues.

3. Regular Maintenance:

Although combi coolers reduce maintenance requirements, regular inspections and maintenance are still essential to ensure continued performance. Follow the manufacturer's guidelines for routine checks and servicing.

4. Monitor Performance:

Monitor the performance of your combi cooler and the overall compressor system. By monitoring performance indicators like temperature levels, you can catch problems before they get worse.

Conclusion:

Screw compressor combi coolers are vital components that significantly enhance the performance and reliability of compressed air systems. By providing effective thermal management, improving efficiency, extending equipment lifespan, and reducing maintenance needs, Industrial enterprises can significantly benefit from combi coolers. Investing in a high-quality combi cooler and ensuring proper installation and maintenance can lead to substantial long-term savings and operational improvements, making them an indispensable part of any screw compressor system.

FAQs

Frequently Ask Questions

A screw compressor combi cooler is a cooling system designed to manage the temperature of both the air and the oil in a screw compressor. It combines air and oil cooling functions in a single, compact unit.

Overheating can cause severe damage to compressor components; hence, thermal management is essential. Failure to manage heat effectively can lead to reduced efficiency, increased maintenance, and potential failure.

Combi coolers maintain optimal air and oil temperatures, ensuring that the compressor operates efficiently. This reduces energy consumption, lowers operational costs, and enhances overall performance.

Yes, by preventing overheating and reducing thermal stress, combi coolers help extend the lifespan of compressor components, resulting in lower maintenance costs and fewer replacements.

Combi coolers provide consistent and effective cooling for both air and oil, reducing the risk of overheating and component failure. This reliability is crucial for industrial applications where downtime can be costly.

Yes, combi coolers are versatile and can be adapted to various industrial applications, including manufacturing, automotive, and construction. They are adaptable to varied settings' unique cooling requirements.

Combi coolers reduce overall maintenance requirements due to their effective cooling capabilities. However, regular inspections and maintenance according to the manufacturer's guidelines are still necessary to ensure optimal performance.